How to Get a Hard Cover Book Printed

Aug 07,2025

Aug 07,2025

SESE

SESE

How to Get a Hard Cover Book Printed: A Step-by-Step Guide

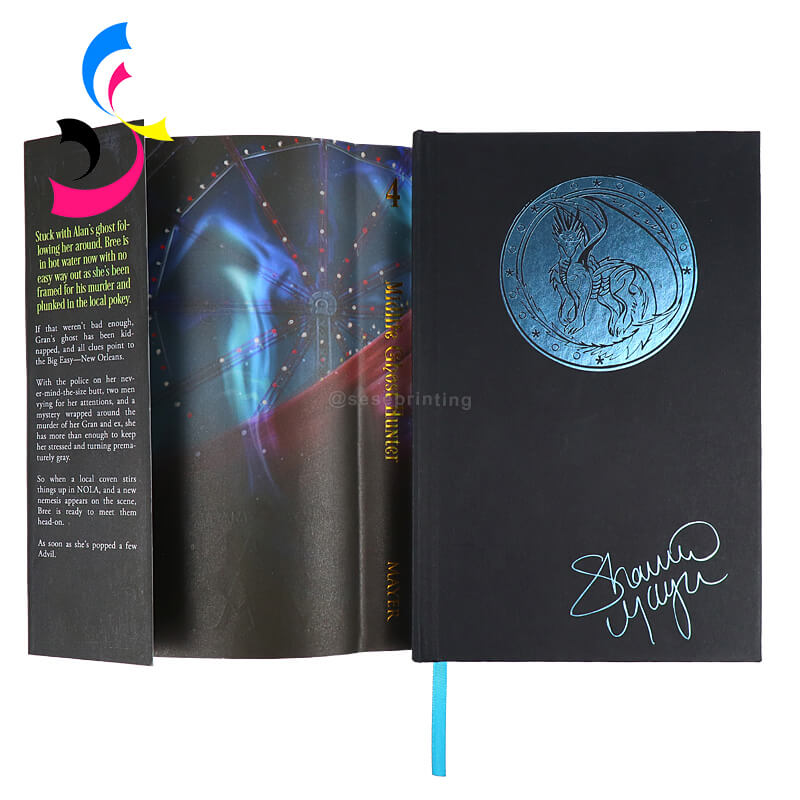

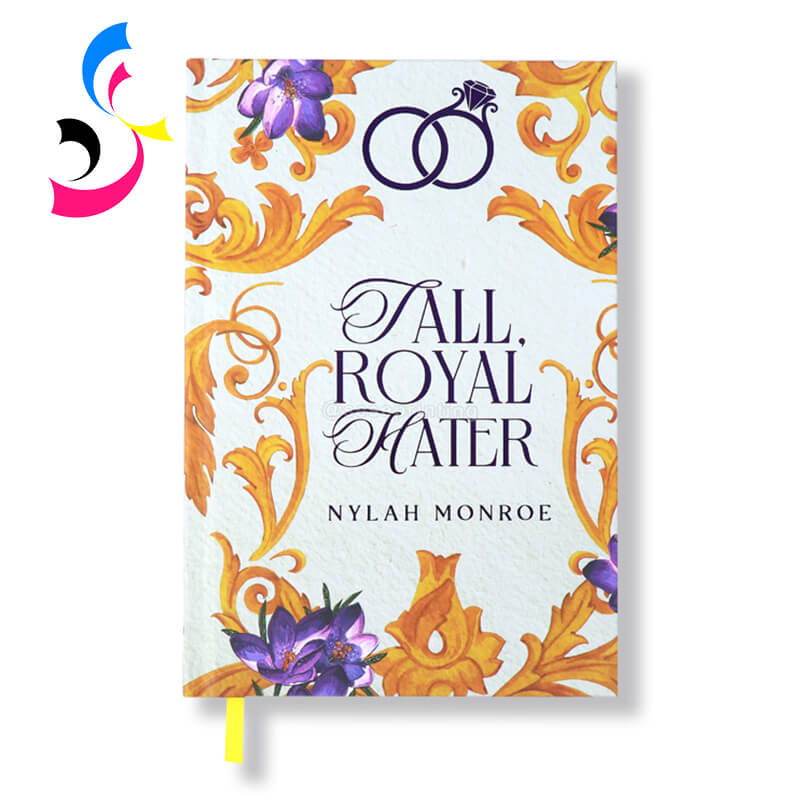

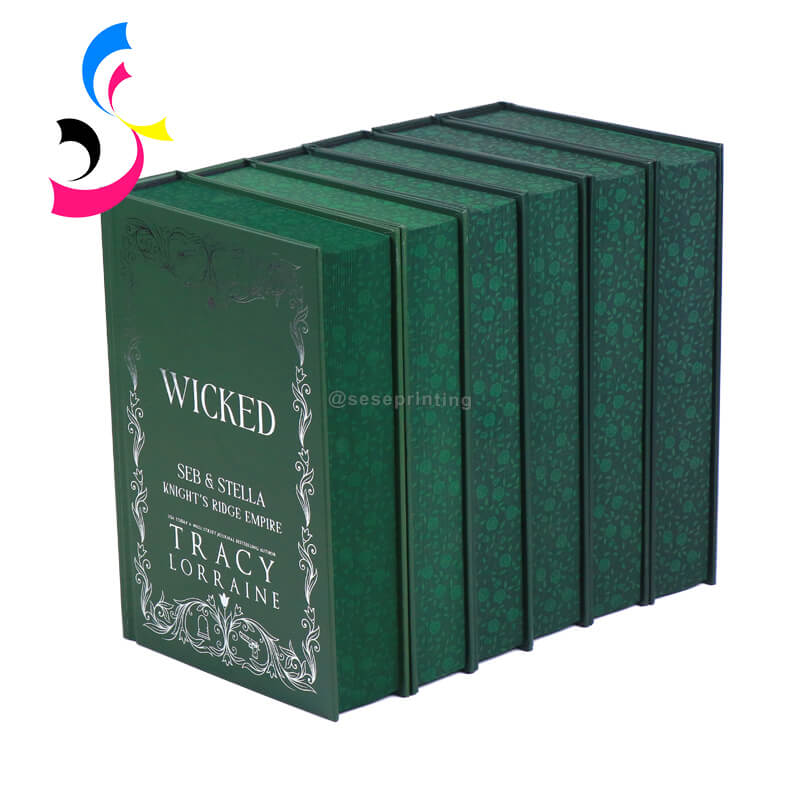

Hardcover books exude quality, durability, and a sense of importance. Whether you're a self-publishing author, a corporation producing a premium report, an artist creating a portfolio, or someone printing a special family history, a hardcover binding elevates your project. While the process involves more steps and investment than paperback printing, the professional result is often worth it. This guide walks you through how to successfully get your custom hardcover book printed.

1. Understanding Hardcover Book Printing

A. What is Hardcover Printing?

Hardcover printing (or case binding) is the process of creating books with rigid, protective outer covers. Unlike paperbacks glued directly to a flexible cover, hardcovers involve constructing a sturdy "case" made of thick cardboard (binder's board) covered with durable material (paper, cloth, leather, etc.). The bound pages (text block) are then securely attached to this case using strong glue and reinforcing fabric or endpapers. This method prioritizes durability, longevity, and a premium presentation.

B. Difference Between Hardcover and Paperback

| Feature | Hardcover Book | Paperback Book |

|---|---|---|

| Cover | Rigid cardboard covered with durable material (cloth, paper, leatherette). | Flexible cardstock, directly glued to the spine. |

| Binding | Typically Smyth-sewn (stitched) signatures glued into a rigid case. Stronger spine. | Almost always perfect binding (pages glued directly to spine). More flexible spine. |

| Durability | Highly durable. Resists damage, lies flatter when open, lasts decades. | Less durable. Spine prone to creasing, covers tear/bend easily. |

| Appearance | Premium, substantial feel. Conveys importance and quality. | Lighter, more casual, portable. Less formal. |

| Cost | Significantly higher per unit due to materials and complex binding. | Lower per unit cost due to simpler materials and binding. |

| Production | More complex process, higher setup costs. Often higher MOQs (e.g., 300). | Simpler, faster production. Lower MOQs common. |

| Common Uses | First editions, special editions, reference books, art/photography books, high-quality fiction/non-fiction, corporate reports, prestigious portfolios, children's books. | Mass-market fiction, trade books, academic texts (sometimes), lower-cost editions, ARCs (Advance Reader Copies). |

C. Components of a Hardcover Book

Cover Boards (Binder's Boards): Thick, rigid cardboard pieces (typically 80pt-120pt thickness) forming the front, back, and spine of the case. Provides structural rigidity.

-

Cover Material: The durable material glued over the cover boards. Options include:

-

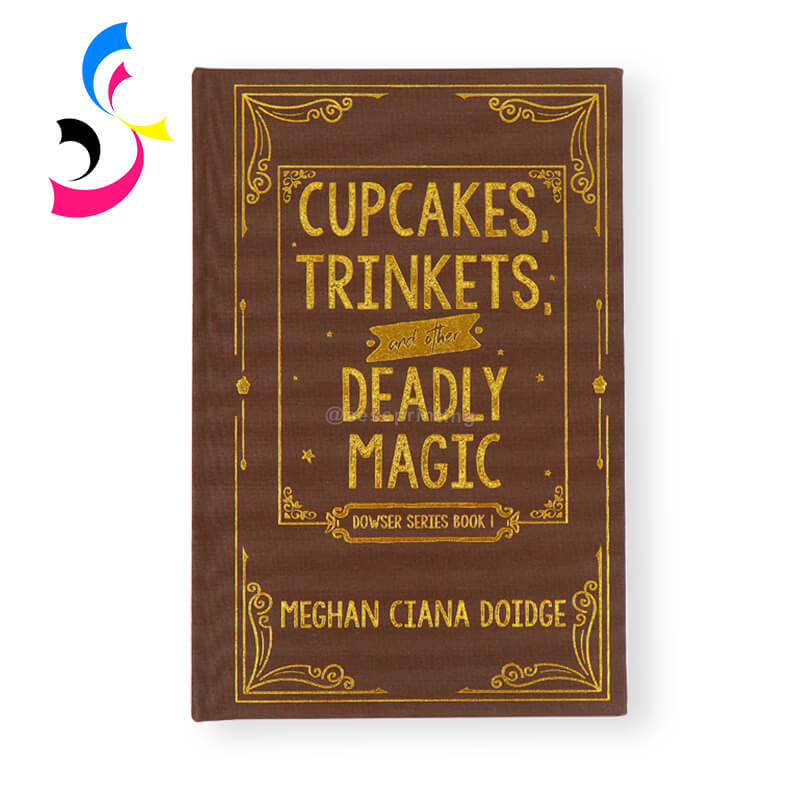

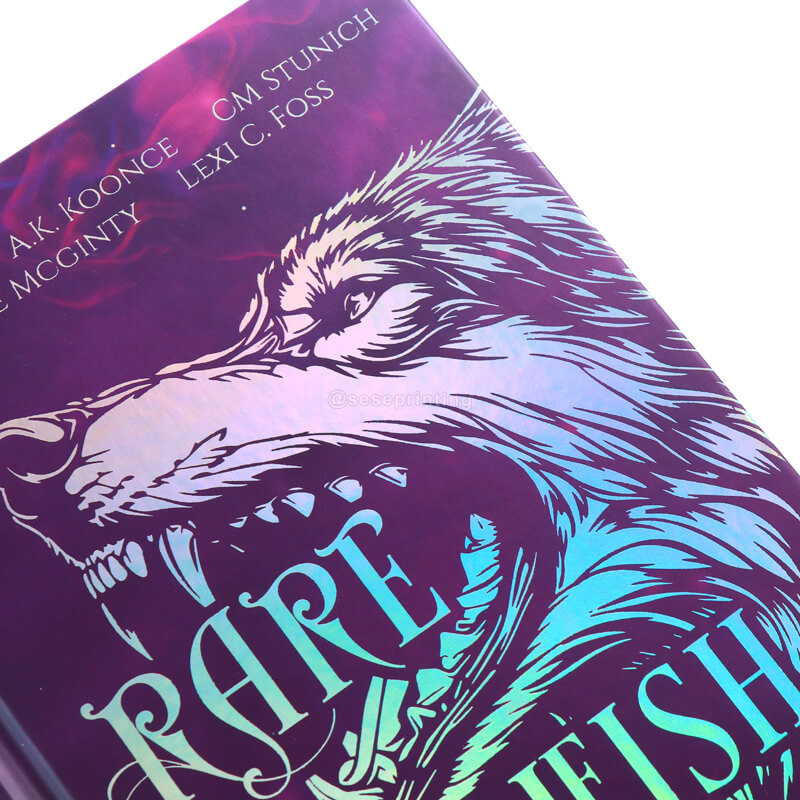

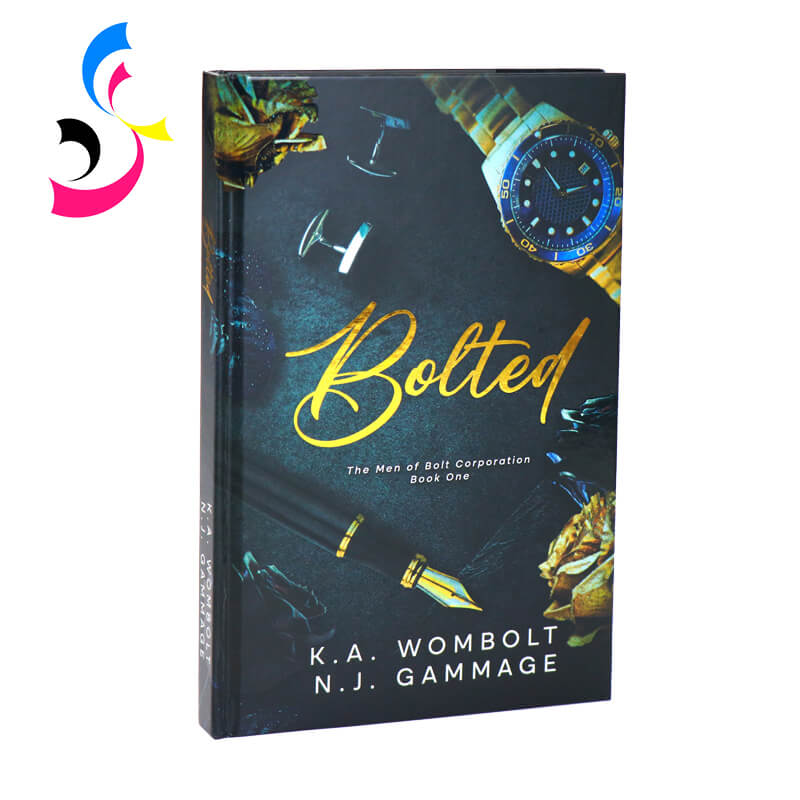

Printed Paper (Casewrap): Most common. Design printed directly onto paper laminated to the boards.

-

Book Cloth (Buckram, Linen): Durable woven fabric. Often used for library/luxury editions. Can be solid color or printed.

-

Synthetic Leather (Leatherette): Imitation leather for a classic, premium look.

-

Printed Laminated Board (Printed Case): High-quality printing directly onto the board itself before lamination (no separate paper layer). Very premium feel.

-

Spine: The rigid part connecting the front and back covers. The cover material wraps around it. Its width is critical and calculated based on page count and paper thickness. Houses the book title/author info.

-

Text Block (Book Block): The actual bound pages of the book. Signatures (groups of pages) are folded, sewn together (Smyth-sewn), and glued.

-

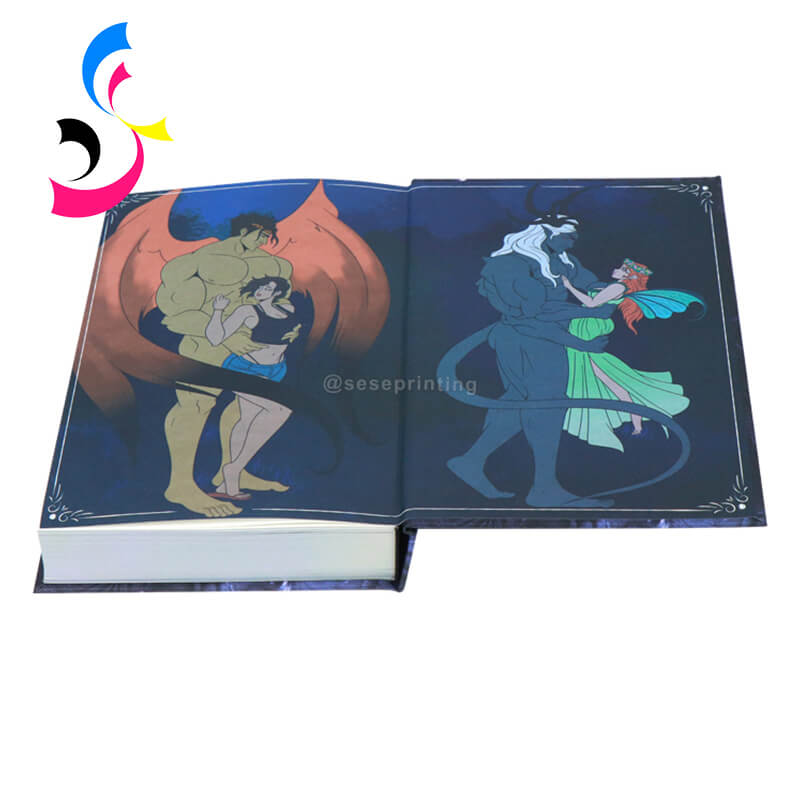

Endpapers (Endsheets): Strong, decorative paper sheets (one glued to the inside front cover, one to the inside back cover). The other side of each is glued to the first/last page of the text block, physically connecting the block to the case. Hides the raw edges of the cover material and boards. Often colored or patterned.

-

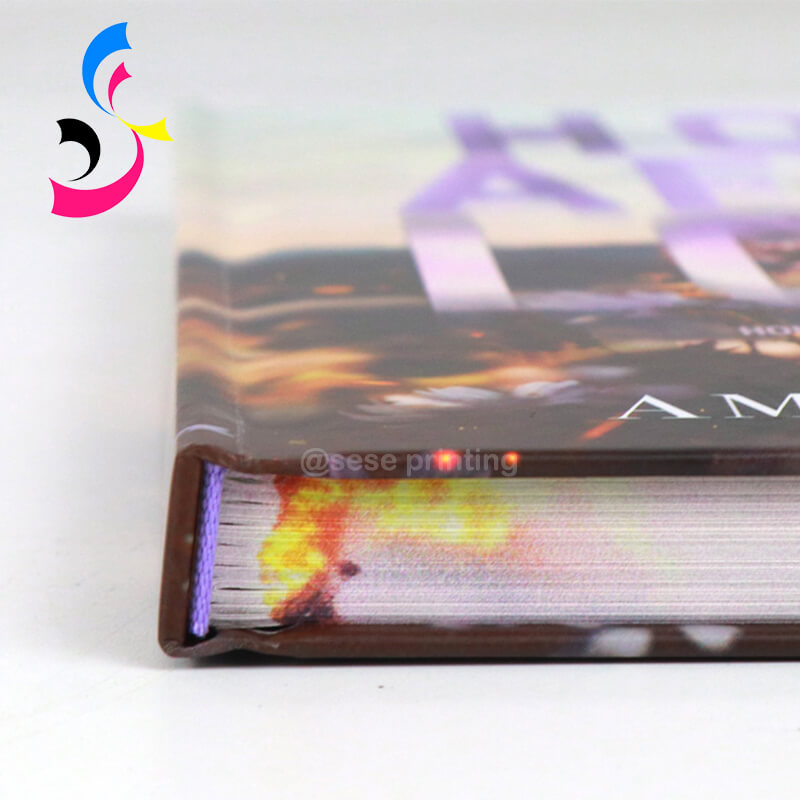

Headbands & Footbands (Optional): Decorative cloth tapes glued to the top (head) and bottom (foot) of the spine within the text block. Originally reinforced binding; now mostly aesthetic.

-

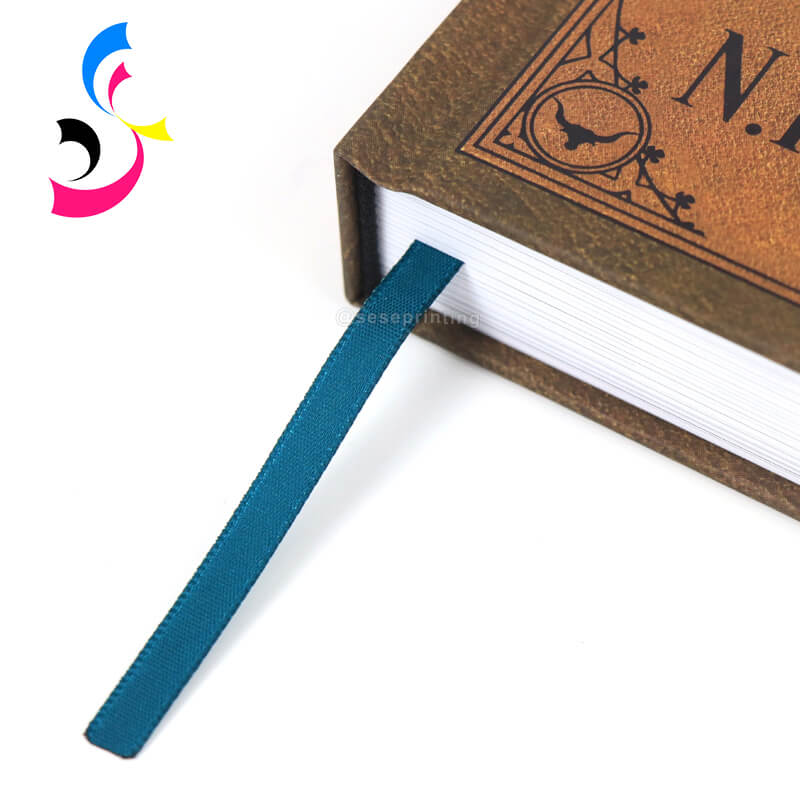

Ribbon Marker (Optional): A woven ribbon bookmark sewn into the spine of the text block at the top.

-

Dust Jacket (Optional): A removable printed paper wrapper that folds around the hardcover case. Provides extra space for design, blurbs, and author info, and protects the underlying cover. Often has flaps that tuck inside the covers.

2. Steps to Print a Custom Hardcover Book

A. Prepare Your Manuscript

-

Finalize Content: Ensure your text is meticulously proofread, edited, and formatted consistently (font, spacing, chapter headings).

-

File Format: Prepare your interior manuscript file (the pages of the book) as a single, print-ready PDF. Common software includes Adobe InDesign (ideal), Affinity Publisher, or even carefully formatted Word documents exported to PDF.

-

Page Count: Know your final page count. This is crucial for spine width calculation on the cover. Page count must be divisible by specific signatures (groups of pages printed together), often 16 or 32 pages. Your printer can advise on requirements.

-

Image Resolution: Ensure all embedded images are high resolution (typically 300 DPI at the intended print size).

B. Choose a Printing Service

-

Specialization: Look for printers experienced in hardcover book printing, especially for lower quantities if needed.

-

Capabilities: Ensure they offer the specific hardcover binding type (casewrap, dust jacket, printed case) and finishes you desire.

-

Quality & Reputation: Read reviews, ask for samples of their hardcover work, and check their minimum order quantities (MOQs). Consider companies like sese printing, we specializated in various book formats including hardcovers – request a quote and samples from us.

-

Communication & Support: Choose a printer with responsive customer service who can guide you through the process.

C. Select Hardcover Specifications

Cover Materials

Board Type: Typically 80pt to 100pt (thick cardboard) for durability.

Cover Paper:

|

|

|

|

Printed Dust Jacket |

Printed Casewrap |

Cloth-bound |

Printed Dust Jacket (gloss/matte laminated) over plain board.

Printed Casewrap (image printed directly on cover with lamination).

Cloth-bound (linen, buckram, or leatherette) with foil stamping.

Hybrid (partial cloth with printed areas).

Binding Method

Sewn Binding: Highest durability (thread-sewn signatures).

Spine Options

|

|

|

Square Spine |

Round Spine |

Square Back: Standard spine.

Rounded & Backed Spine: More premium, durable for thicker books.

Interior Paper

Weight: 70#–100# text weight (thicker for art/photo books).

Finish: Uncoated (matte), coated (glossy/satin), or specialty (cream, recycled).

Additional Features

|

|

|

|

|

|

Headbands & Tailbands |

Ribbon Marker |

Debossing |

Embossing |

Foil Stamping |

|

|

|

|

|

Printed Endpheets |

Spot UV |

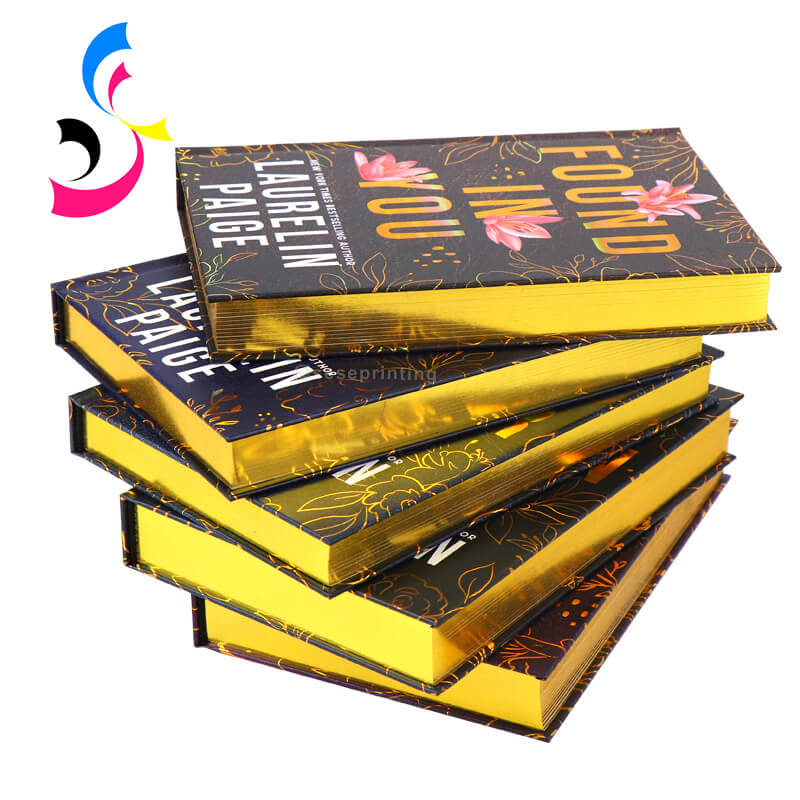

Gilded Edges |

Sprayed/Stenciled Edges |

Headbands & Tailbands (decorative fabric at spine ends).

Ribbon Marker (sewn-in bookmark).

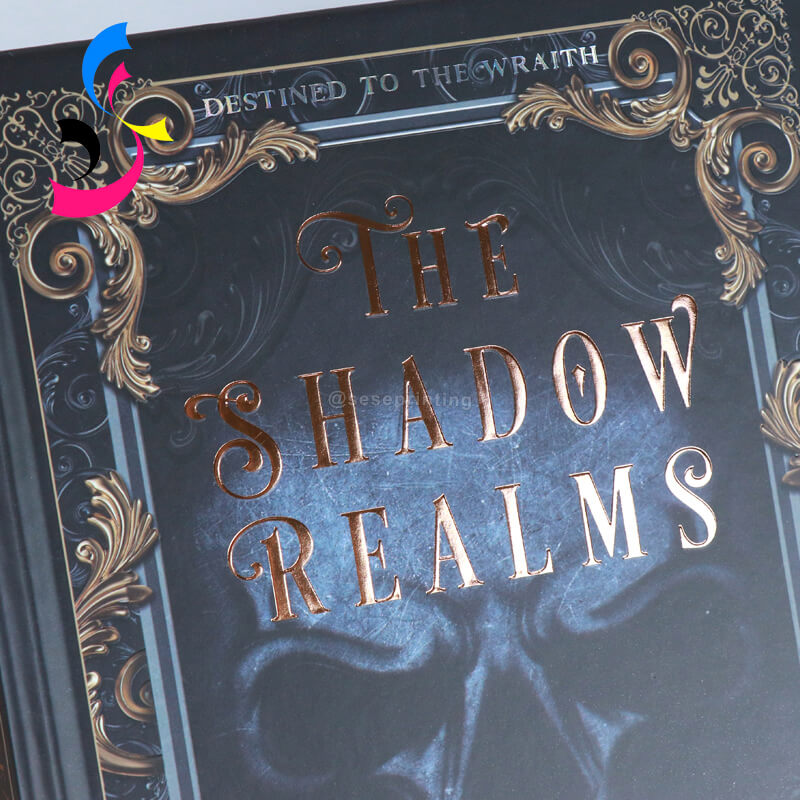

Debossing/Embossing/Foil Stamping (for title/design).

Printed Endpheets (decorative inside covers).

Spot UV (selective glossy highlights).

Gilded/Sprayed/Stenciled Edges ( Gold/silver foil or colored paint on page edges).

Size & Dimensions

Common trim sizes: 6×9", 5.5×8.5", 8×10" (or custom).

Lamination (Dust Jacket/Casewrap)

Gloss (shiny, vibrant colors).

Matte (elegant, non-reflective).

Soft-Touch (velvet-like feel).

D. Design the Cover & Interior

Cover Design: Create your cover artwork according to the printer's exact template. This template includes:

-

Front and back panel dimensions.

-

Spine width: Crucially calculated based on page count and paper thickness (your printer will provide the formula).

-

Bleed area (usually 3mm/0.125" extra beyond the trim edge).

-

Safe zones (keep critical text/elements away from edges).

Interior Layout: Ensure consistent margins, proper gutter (inner margin) for binding, headers/footers, and image placement. Pay attention to typography for readability.

File Setup: Deliver both cover and interior files as high-resolution PDFs, with bleeds and crops marks included. Use CMYK color mode.

E. Order a Proof

-

Essential Step: Never skip this! Order a physical proof copy before the full print run.

-

Types: Options range from a basic digital proof (shows layout/color roughly) to a physical "dummy" with your actual cover materials and binding (most accurate but more expensive).

-

Check Meticulously: Inspect color accuracy, print quality, trim, binding integrity, paper feel, cover finishes, and overall construction. Verify text and images. Make final corrections if needed.

F. Place Your Order

-

Once you approve the proof, provide the printer with your final print-ready files.

-

Confirm all specifications: Quantity, paper stock for interior and cover, binding details, finishes, shipping address, and delivery timeline.

-

Review the final invoice and payment terms.

3. Costs and Minimum Orders (MOQ)

Significantly Higher than Paperbacks: Hardcover production involves more materials (boards, glue, cover material) and complex binding processes, leading to a higher per-unit cost.

Key Cost Factors:

-

Quantity (higher quantities lower the per-unit cost).

-

Page count and paper quality (interior).

-

Cover material and complexity (casewrap vs. dust jacket vs. printed case).

-

Binding method (sewn vs. glued).

-

Special finishes (foil, UV, embossing).

-

Shipping.

Minimum Order Quantity (MOQ): The MOQ for custom hardcover books with sese printing is 300 pieces, which helps reduce per-unit costs through bulk production. Pricing depends on factors like book size, page count, paper quality, and special finishes. Request a detailed quote upfront to plan your budget accordingly.

4. Tips for a Professional Result

-

Start with Printers: Research printers early and get their specific guidelines for file setup, spine calculation, and specs. Design to their requirements.

-

Invest in Design: Professional cover and interior design are paramount for a quality hardcover. If design isn't your strength, hire a professional book designer.

-

Spine Width is Critical: An incorrectly calculated spine width ruins the look and can cause binding issues. Double-check with your printer.

-

Paper Matters: Choose interior paper appropriate for the content (e.g., coated for high-quality photos, uncoated for novels). Select cover materials that match the book's purpose and feel.

-

Prioritize Proofing: The physical proof is your last chance to catch errors. Inspect it under good light and take your time.

-

Budget Realistically: Factor in all costs – design, proofing, printing, and shipping. Hardcovers are an investment.

-

Communicate Clearly: Maintain open communication with your printer throughout the process. Ask questions.

Home

Home

Unlock Luxury with Sese Printing: Mastering Foil Stamping File Prep (PDF vs. AI)

Unlock Luxury with Sese Printing: Mastering Foil Stamping File Prep (PDF vs. AI)  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address