How to Make a Graphic Novel

Jul 30,2025

Jul 30,2025

SESE

SESE

How to Make a Graphic Novel: From Creation to Custom Printing

Creating a graphic novel is an exciting journey that combines storytelling, visual art, and publishing. Whether you’re an independent creator or part of a creative team, understanding each step in the process will help you bring your vision to life—and into readers’ hands. Here's a comprehensive guide to making your own graphic novel, with insights on custom printing options to make it truly stand out.

1. Develop Your Concept and Storyline

Every great graphic novel begins with a compelling concept. Start by defining your story’s genre, themes, and key message. Develop rich characters and a plot that resonates emotionally with your audience. Whether it’s a dystopian sci-fi, slice-of-life drama, or historical fiction, your concept sets the foundation for everything else.

2. Scriptwriting and Page Planning

Choose Your Script Format: Full Script (detailed panel descriptions/dialogue) or Marvel Method (plot outline given to artist first). Consistency is key.

Write Visually: Describe actions, expressions, and settings clearly. Remember: show, don't just tell.

Break Down into Pages & Panels: Determine how much story fits per page. Plan panel sequences, layouts (splash pages, grids), and pacing. Storyboarding thumbnails is invaluable here.

Craft Compelling Dialogue & Text: Keep dialogue concise and character-specific. Integrate narration/sound effects effectively.

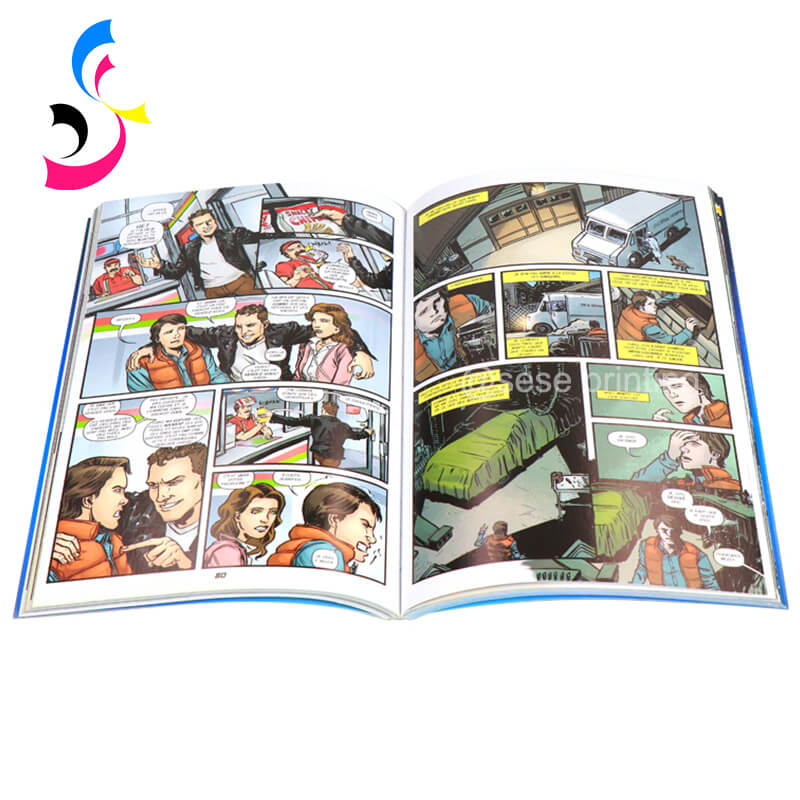

3. Create the Artwork

Penciling: Sketch the layouts, characters, and backgrounds based on the script/thumbnails. Focus on composition, perspective, and storytelling flow.

Inking: Refine the pencil lines, adding weight, depth, texture, and clarity. Defines the final look.

Coloring (if applicable): Sets mood, atmosphere, and directs the reader's eye. Choose palettes intentionally (flat colors, gradients, painterly styles).

Lettering: Add dialogue, captions, and sound effects. Ensure readability and integrate seamlessly with the art. Consider font style and balloon placement carefully.

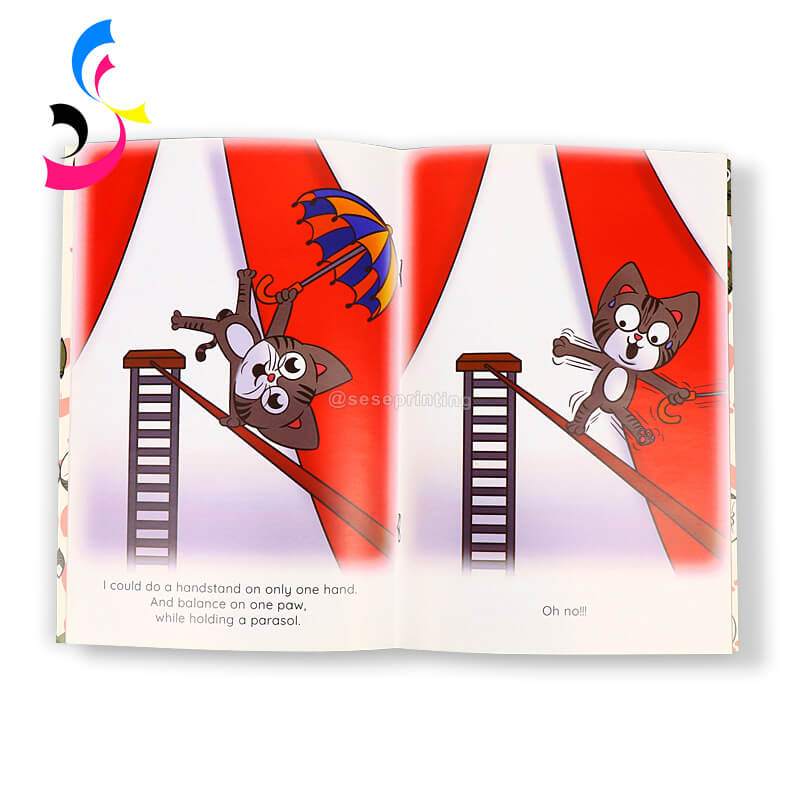

4. Choosing the Right Format for Printing

Standard Graphic Novel: Most common, similar to a trade paperback (usually 6"x9" or 7"x10").

Manga Size: Taller and narrower (typically 5"x7.5").

Oversized/Hardcover: Larger format (e.g., 8.5"x11") for greater visual impact, often used for special editions.

Consider Your Audience & Budget: What format do readers expect for your genre? What production cost can you handle?

5. Custom Printing Options to Make Your Graphic Novel Stand Out

|

|

|

|

|

Spot UV |

Foil Stamping |

Embossing |

Debossing |

|

|

|

|

|

Sprayed Edges |

Printed Edge Designs |

Matte Lamination |

Glossy Lamination |

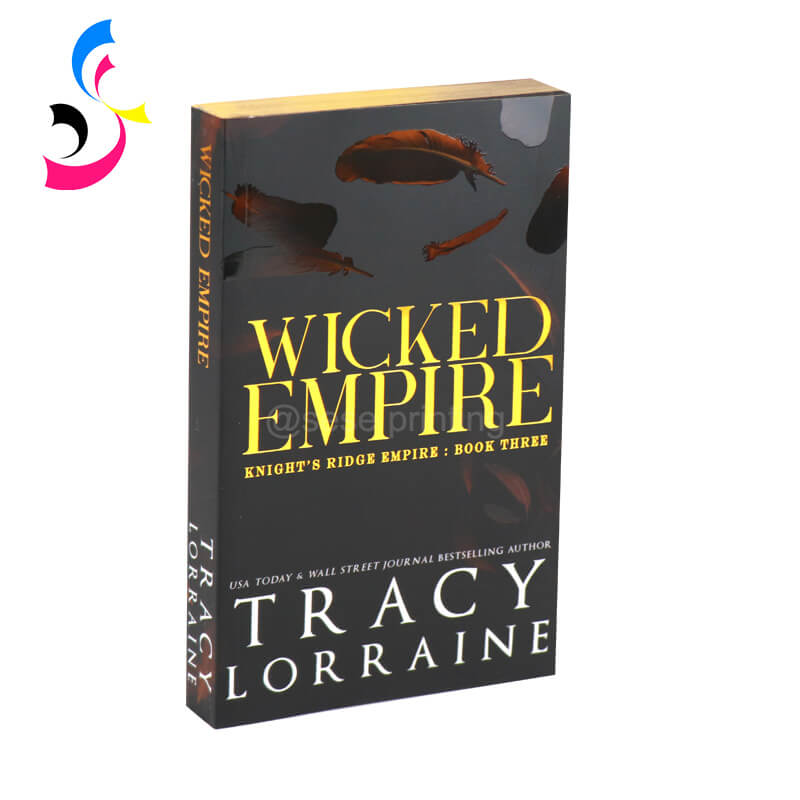

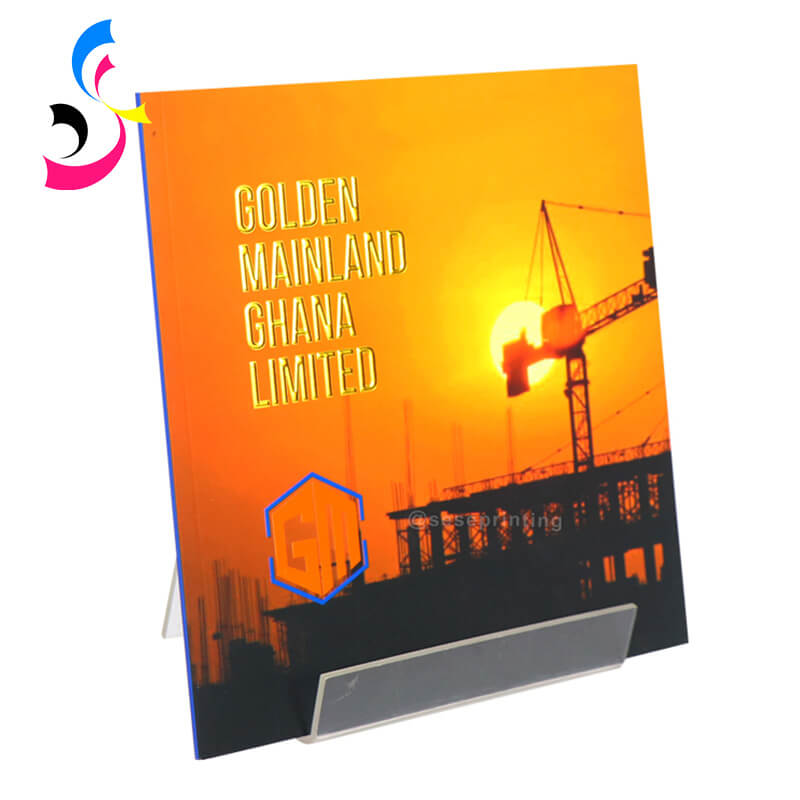

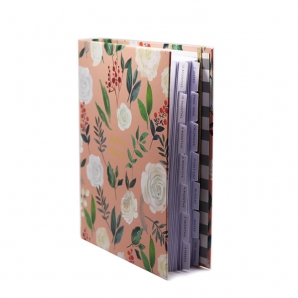

Spot UV: Add glossy highlights to specific areas (title, character elements) on the cover for texture and shine.

Foil Stamping: Metallic gold, silver, or colored foil accents for a luxurious, eye-catching cover.

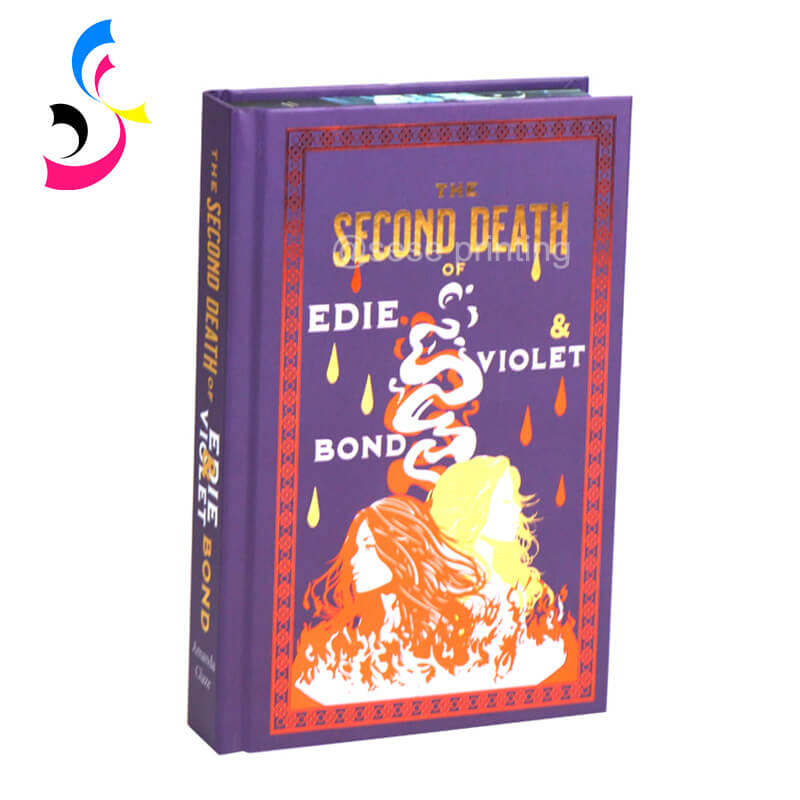

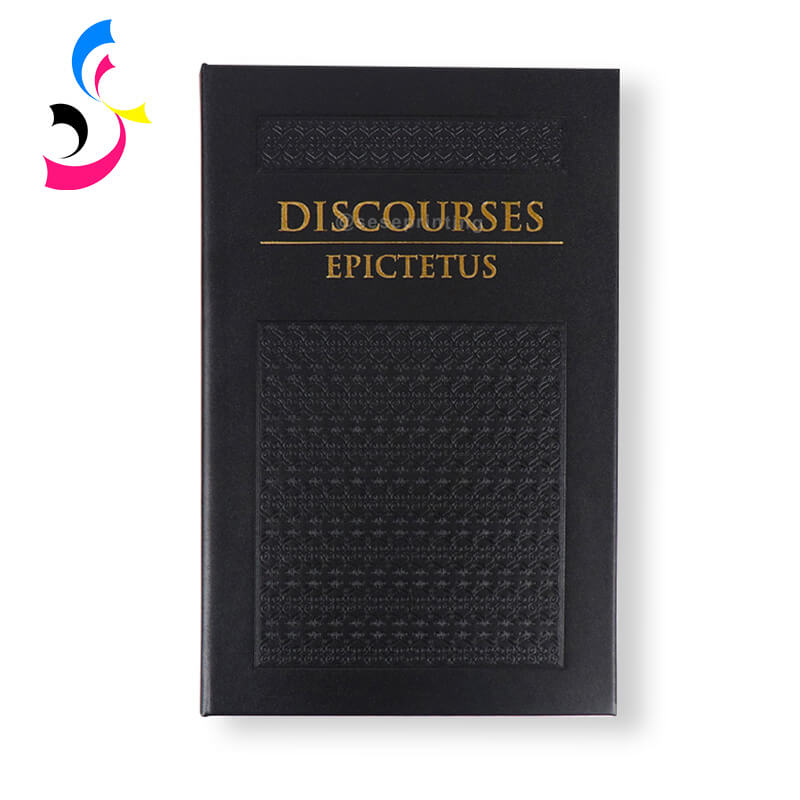

Embossing/Debossing: Create raised (embossed) or recessed (debossed) areas on the cover for a sophisticated tactile feel.

Die-Cutting: Cut unique shapes into the cover or dust jacket for a distinctive look.

Special Inks: Consider Pantone spot colors for brand consistency or unique effects beyond standard CMYK.

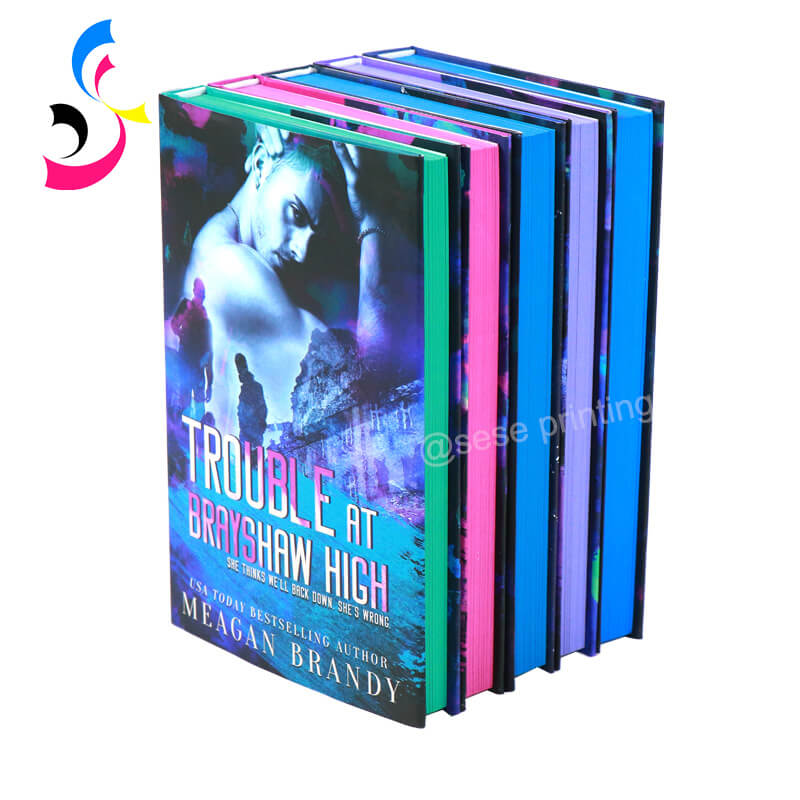

Sprayed Edges: Solid or gradient color applied to the edges of the book block, adding a bold, customized look that enhances shelf appeal.

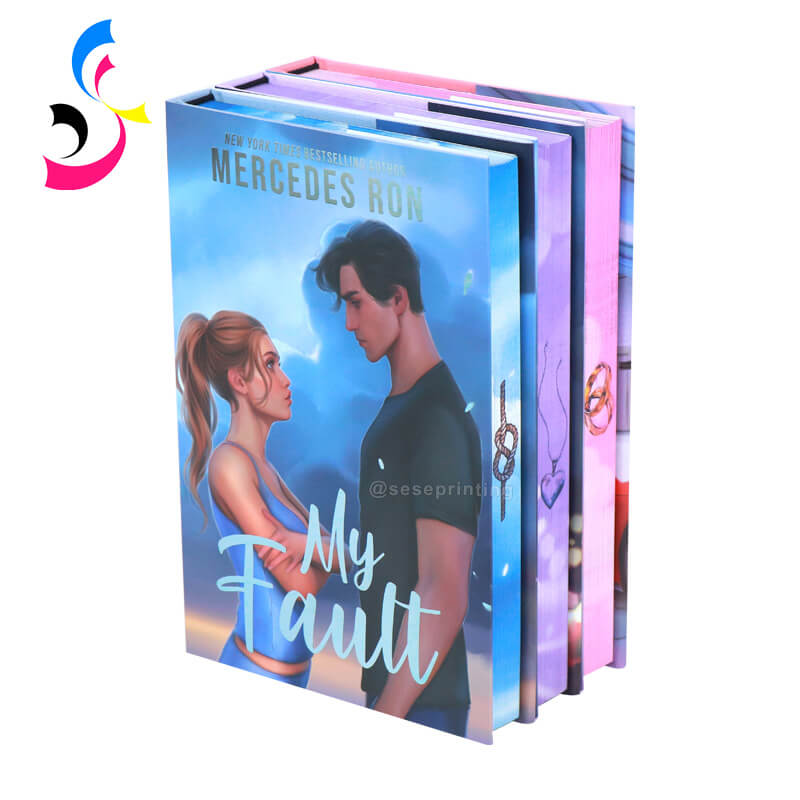

Matte or Glossy Lamination: A protective coating on the cover that provides either a smooth, non-reflective finish (matte) or a shiny, vibrant surface (glossy), boosting durability and visual impact.

Stenciled or Printed Edge Designs: Detailed patterns, images, or text printed directly onto the page edges using stencil or digital techniques, perfect for adding unique branding or storytelling elements.

6. Paper Choices for Graphic Novels

Interior Pages:

|

|

|

Coated Paper |

Uncoated Paper |

-

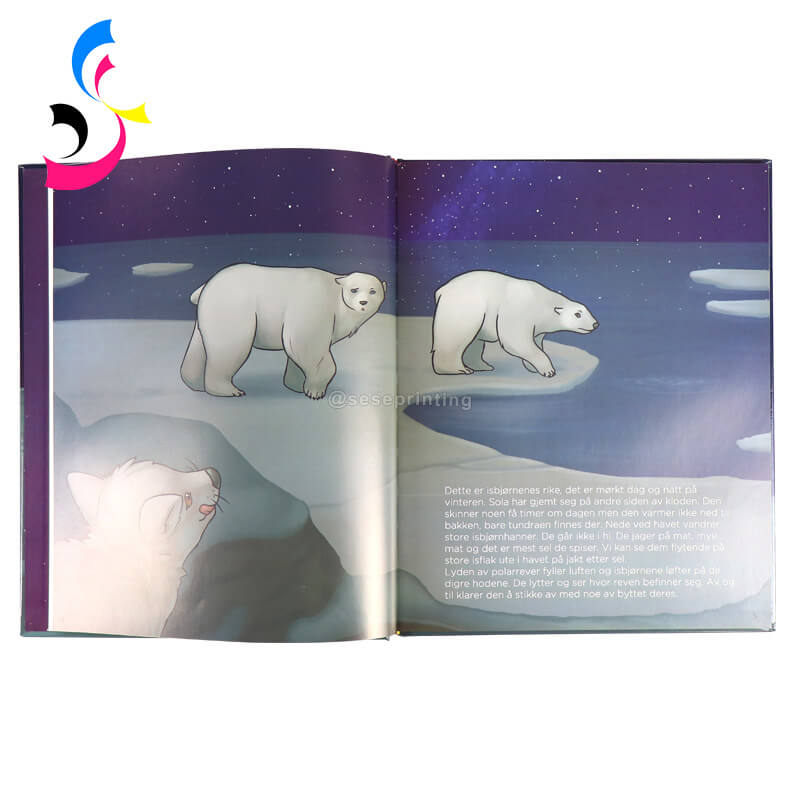

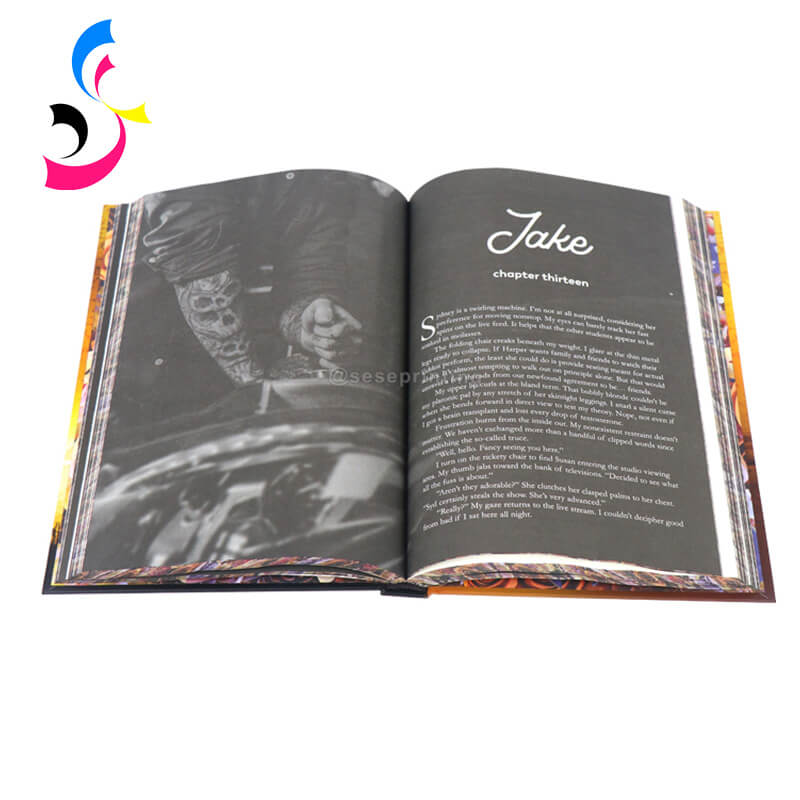

Coated (Gloss/Matte/Satin): Essential for vibrant color reproduction. Gloss offers maximum vibrancy but glare; Matte reduces glare and feels premium; Satin is a popular middle ground.

-

Uncoated: Rarely used for full-color graphic novels (dulls colors), sometimes seen for B&W with a specific aesthetic.

-

Weight: 70lb to 100lb text weight is standard. Thicker paper (100lb+) feels more substantial and reduces bleed-through but increases cost and thickness. Consider opacity.

Covers:

-

Cardstock: Essential for paperback covers. 10pt to 14pt is common. Can be coated (C1S) or uncoated.

-

Lamination: Gloss, Matte, or Soft-Touch lamination protects the cover and enhances appearance/durability. Matte lamination is often preferred for a premium feel.

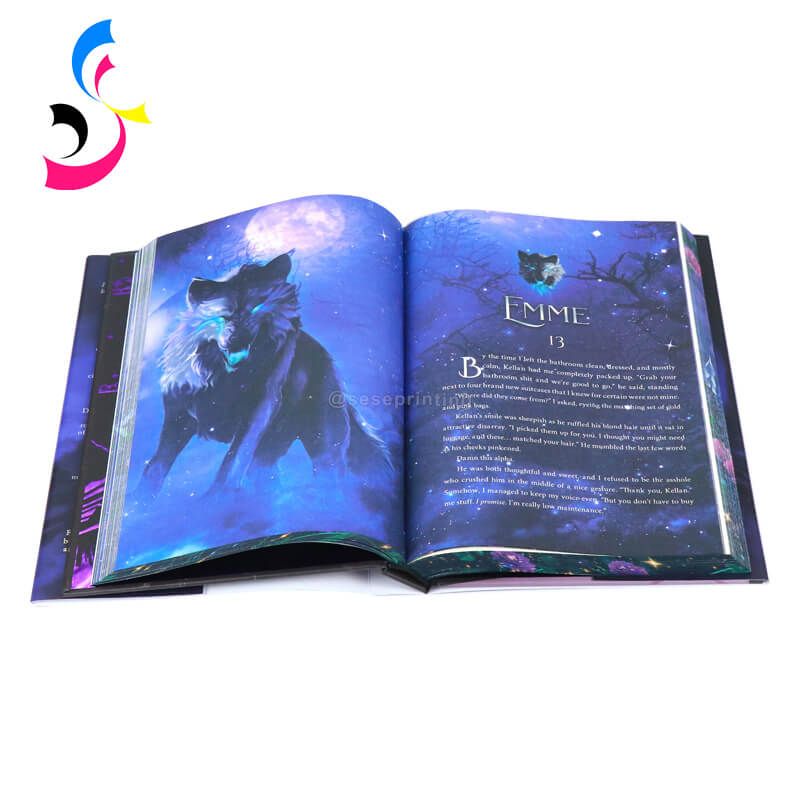

7. Binding Methods

|

|

|

|

Perfect Binding |

Saddle Stitching |

Case Bound |

Perfect Binding (Paperback): Pages glued into a spine. Most common and cost-effective for graphic novels. Needs a minimum page count (usually 48+ pages). Lies relatively flat when opened.

Saddle-Stitching (Stapled): Pages folded and stapled through the spine. Only suitable for very low page counts (typically under 80 pages). Less durable.

Hardcover (Case Binding): Pages sewn into signatures, glued into a rigid board cover wrapped with paper or cloth. Most durable and premium option. Includes dust jackets. Smyth sewing offers the flattest lay-open.

8. Partnering with a Custom Book Printer

Why Specialized Matters: Graphic novels demand high-quality color reproduction, specific paper stocks, and binding that can handle heavy ink coverage and frequent handling. A printer experienced in comics understands these nuances.

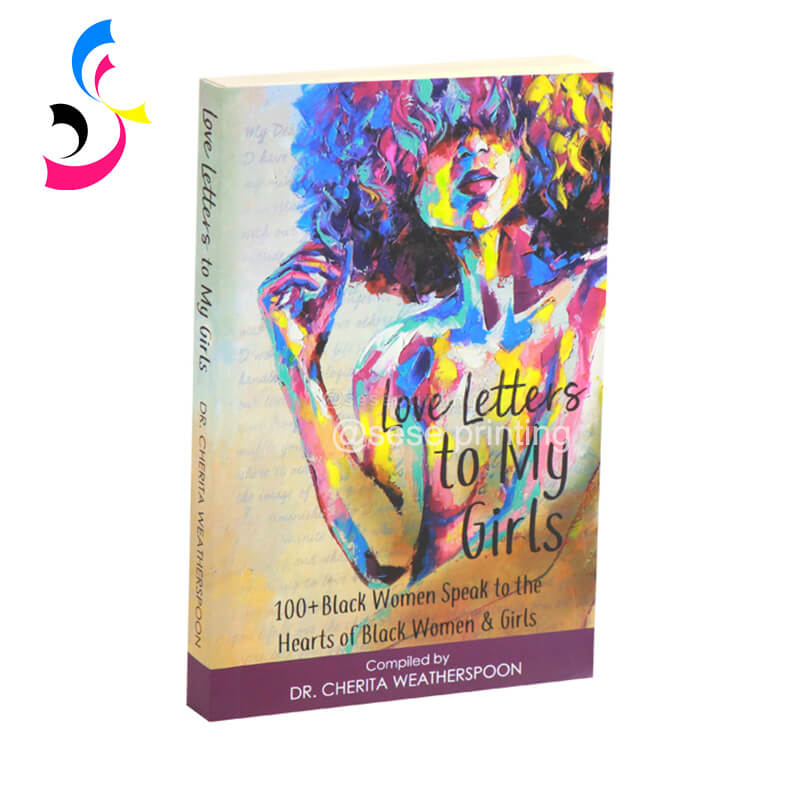

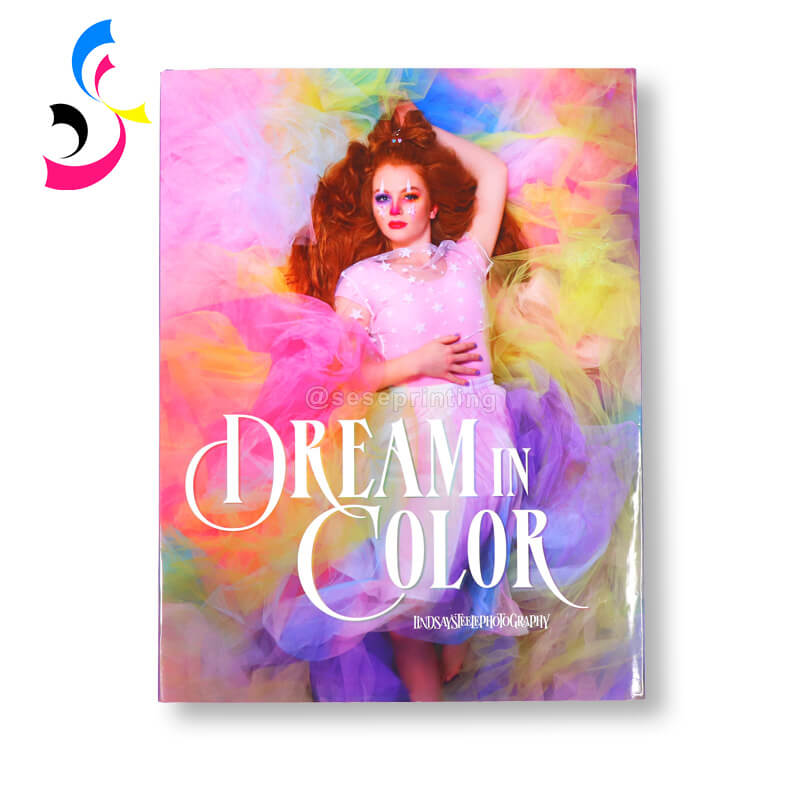

Enter SESE Printing: Companies like SESE Printing specialize in custom book printing, offering tailored solutions perfect for graphic novels. We provide:

-

Expertise in handling complex artwork and color matching.

-

A wide range of paper stocks and binding options.

-

Customization features like spot UV, foil stamping, and embossing.

-

Guidance on format, specs, and cost-effective production.

-

Options for both small print runs (for crowdfunding or initial sales) and larger quantities.

Collaboration: Work closely with your printer. Provide high-resolution files, discuss your vision, request paper samples, and get proofs before the full print run.

9. Print and Distribute Your Graphic Novel

Final File Prep: Ensure your PDFs meet the printer's specifications (bleed, trim, resolution, color profile - usually CMYK).

Proofing: Carefully review physical or digital proofs for any errors in color, text, or alignment.

Print Run: Decide on quantity based on your budget, storage, and sales strategy (pre-orders help gauge demand).

Distribution Channels:

-

Direct Sales: Your website, conventions, local bookstores/comic shops (consignment or wholesale).

-

Online Retailers: Amazon (KDP or FBA), Barnes & Noble online.

-

Comic Distributors: Diamond Comic Distributors (primary for comic shops globally), Lunar Distribution, Penguin Random House Publisher Services. Getting into major distributors often requires proven demand.

Home

Home

How to Get a Hard Cover Book Printed

How to Get a Hard Cover Book Printed  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address